Professional mechanical pickling service for stainless steel in Bologna

The company Gulinelli, with headquarters in Bologna and also operating in the province, offers a specialized third-party processing service for the pickling of stainless steelThanks to the use of cutting-edge systems, the company is able to guarantee treatments of immersion pickling, chemical and electrolytic, to spray And manualThe processes of mechanical pickling of stainless steel and of passivation are performed in compliance with the rigorous ASTM A380 and ASTM A967 standards, ensuring the maximum quality and reliability of the results obtained.

The pickling of stainless steel It is particularly advantageous for products with welds, which can compromise the material's corrosion resistance. Thanks to Gulinelli's specialized skills and experience, customers can confidently rely on a professional and targeted service, able to satisfy the most specific needs and guarantee optimal results in terms of quality and durability over time.

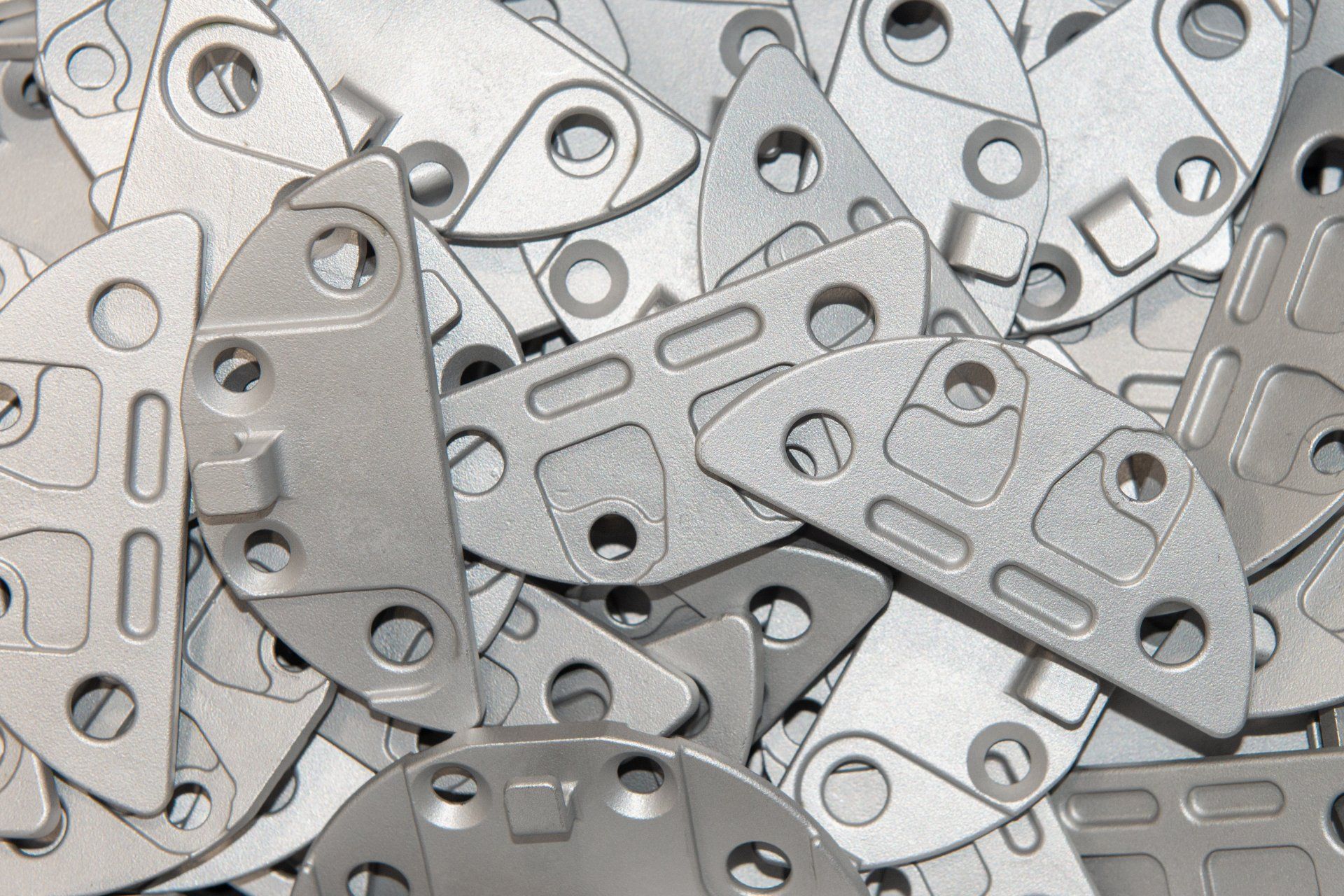

This technique, which uses specific abrasive tools, allows for the removal of damaged or contaminated surface layers, ensuring a uniform, high-quality finish. In addition to improving the aesthetic appearance, the mechanical pickling of stainless steel is crucial to prepare the metal for subsequent treatments, such as painting or the galvanization.

One of the main correlates of the pickling of stainless steel it is the passivation. This chemical treatment, often performed after the pickling, serves to further improve resistance to metal corrosionPassivation creates a protective layer ofoxide on the surface of stainless steel, increasing the durability of the material and its resistance to chemical and atmospheric agents.

The importance of this process is not limited only to the surface quality of the metal. pickling of stainless steel It is also essential for ensuring the safety and reliability of steel structures. In many industrial sectors, from shipbuilding to aerospace, including the food and pharmaceutical industries, pickled and passivated stainless steel guarantees reliability and longevity.

A COMPANY SPECIALIZED IN STAINLESS STEEL PICKLING PROCESSES

The pickling of stainless steel it is an essential phase in the process of stainless steel production: involves the removal of impurities and contaminants from the metal surface, ensuring that it is free from corrosion and other types of damage.

The mechanical pickling of stainless steel plays a key role in ensuring the production of stainless steel products High-quality. Not only does it remove impurities, but it also improves appearance and durability, making it an essential step in the manufacturing process.

Throughout Italy, the Gulinelli company is a leading company in surface treatments related to mechanical pickling of stainless steel in Bologna.

The mechanical pickling of stainless steel It is a technique that requires great skill and the use of specialized equipmentThe choice of tools and abrasive materials is crucial to achieving optimal results without damaging the metal. Only experienced professionals can assess the metal's condition and apply the most suitable treatment for each specific need.

Another important aspect of this treatment is its ability to improve the hygienic properties of the metal. In sectors such as the food and pharmaceutical industries, where cleanliness and hygiene are essential, a pickled stainless steel It's the ideal choice. Removing impurities and contaminants from the metal surface reduces the risk of bacterial growth and facilitates cleaning and maintenance of equipment.

For more information on the Mechanical pickling of stainless steel, quotes or consultations, do not hesitate to contact us by email or phone.